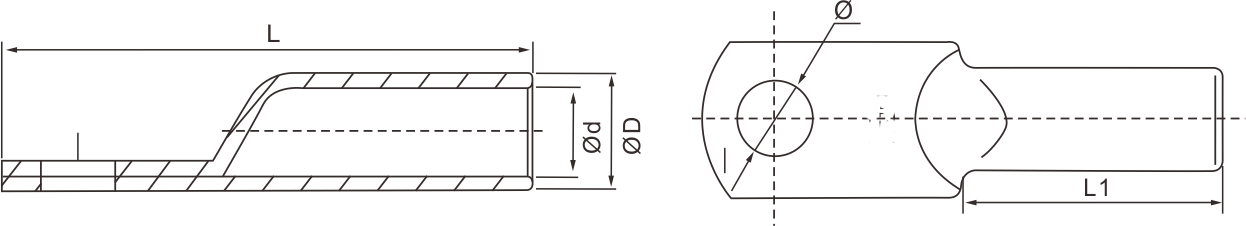

| Type | Ø | D | d | L | L1 |

| DT(G)-10 | 6.5 | 8 | 5 | 51 | 28 |

| DT(G)-16 | 6.5 | 9 | 6 | 57 | 32 |

| DT(G)-25 | 8.5 | 10 | 7 | 61 | 32 |

| DT(G)-35 | 8.5 | 11 | 8.5 | 66 | 36 |

| DT(G)-50 | 8.5 | 13 | 10 | 72 | 38 |

| DT(G)-70 | 10.5 | 15 | 12 | 80 | 43 |

| DT(G)-95 | 10.5 | 18 | 14 | 85 | 44 |

| DT(G)-120 | 12.5 | 20 | 15 | 97 | 51 |

| DT(G)-150 | 12.5 | 22 | 17 | 102 | 53 |

| DT(G)-185 | 14.5 | 25 | 19 | 113 | 54 |

| DT(G)-240 | 16.5 | 27 | 21 | 118 | 56 |

| DT(G)-300 | 16.5 | 30 | 24 | 128 | 62 |

| DT(G)-400 | 21.0 | 34 | 26 | 150 | 65 |

| DT(G)-500 | 21.0 | 38 | 30 | 170 | 70 |

| DT(G)-630 | 21.0 | 45 | 35 | 200 | 80 |

As a kind of connector, the terminal is an important component in the electrical industry. It plays an irreplaceable and non-negligible role. Because engineers and technicians firstly check the interface during maintenance. That is to say, the terminal starts with the terminal. The design is particularly important. It is convenient and simple to use. You only need to press it with a vise to complete the connection. You can directly insert the wire into the wiring hole of the terminal, and the connection can be completed by pressing or spinning in one simple action. If it is equipped with special wiring pliers for connection, the effect is better, faster, and the connection rate is 100%, which plays a significant role in telephone and network wiring projects. 1. Screw connection method of terminal block Screw connection is a connection method using screw terminal blocks. Pay attention to the maximum and minimum cross-sections of the wires allowed to be connected, as well as the maximum tightening torque allowed by screws of different specifications. 2. The welding connection method of the terminal block The most common type of soldering is soldering. The most important thing for soldering connection is the continuity of the metal between the solder and the surface to be soldered. Therefore, solderability is important for cold-pressed terminals. The most common coatings on the solder side of the wire ring terminal are tin alloy, silver and gold. The reed type contact has the welding piece type, the punching welding piece type and the notched welding piece type for the common welding end: the pinhole contact has the drilling arc notch type for the common welding end. 3. Crimping connection method of terminal block Crimping is a technique for compressing and displacing metal within specified limits and connecting wires to contact pairs. A good crimp connection can produce metal mutual fusion flow, so that the wire and the contact pair material symmetrically deform. This connection is similar to a cold-welded connection, which can obtain better mechanical strength and electrical continuity, and it can withstand more severe environmental conditions. 4. Winding method of terminal block Winding is to wind the wire directly on the angular contact winding post. During winding, the wire is wound under controlled tension, and pressed into and fixed at the corners of the contact piece winding post to form an air-tight contact.

As a kind of connector, the terminal is an important component in the electrical industry. It plays an irreplaceable and non-negligible role. Because engineers and technicians firstly check the interface during maintenance. That is to say, the terminal starts with the terminal. The design is particularly important. It is convenient and simple to use. You only need to press it with a vise to complete the connection. You can directly insert the wire into the wiring hole of the terminal, and the connection can be completed by pressing or spinning in one simple action. If it is equipped with special wiring pliers for connection, the effect is better, faster, and the connection rate is 100%, which plays a significant role in telephone and network wiring projects. 1. Screw connection method of terminal block Screw connection is a connection method using screw terminal blocks. Pay attention to the maximum and minimum cross-sections of the wires allowed to be connected, as well as the maximum tightening torque allowed by screws of different specifications. 2. The welding connection method of the terminal block The most common type of soldering is soldering. The most important thing for soldering connection is the continuity of the metal between the solder and the surface to be soldered. Therefore, solderability is important for cold-pressed terminals. The most common coatings on the solder side of the wire ring terminal are tin alloy, silver and gold. The reed type contact has the welding piece type, the punching welding piece type and the notched welding piece type for the common welding end: the pinhole contact has the drilling arc notch type for the common welding end. 3. Crimping connection method of terminal block Crimping is a technique for compressing and displacing metal within specified limits and connecting wires to contact pairs. A good crimp connection can produce metal mutual fusion flow, so that the wire and the contact pair material symmetrically deform. This connection is similar to a cold-welded connection, which can obtain better mechanical strength and electrical continuity, and it can withstand more severe environmental conditions. 4. Winding method of terminal block Winding is to wind the wire directly on the angular contact winding post. During winding, the wire is wound under controlled tension, and pressed into and fixed at the corners of the contact piece winding post to form an air-tight contact.